Call Us08045812114

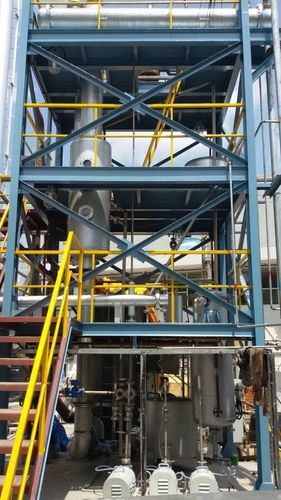

Plate Type Evaporator

1000000 INR

Product Details:

- Type Plate Type Evaporator

- Material Stainless Steel

- Automatic Grade Automatic

- Drive Type Electric

- Voltage 120-440 Volt (v)

- Color Silver

- Warranty 1 Year

- Click to View more

X

Plate Type Evaporator Price And Quantity

- 1 Plant

- 1000000 INR

Plate Type Evaporator Product Specifications

- 1 Year

- Automatic

- Silver

- 120-440 Volt (v)

- Electric

- Plate Type Evaporator

- Stainless Steel

Plate Type Evaporator Trade Information

- Cash in Advance (CID) Cash Advance (CA)

- 1 Plant Per Day

- 1-2 Months

- All India

Product Description

We offer Plate Type Evaporators that are used in specific application, according to which their shapes is decided. Also known as plate heat exchangers, these are used to process liquors that are prone to crystallization or scaling. In these evaporators, the circulation of liquid is done at an elevated rate through calandria. Within this unit, boiling is averted via a hydrostatic head that is sustained at a position raised to the top tube plate. When the absolute pressures reaches a point that is somewhat less than the pressure of tube bundle, liquid is forced to enter in the separator. Upon this action, the liquid converts into vapor that is flashed out. It is one of the general different types of evaporators and it's design can be customized as per client's needs.

Key Points

- Rust resistant recirculating pumps and durable circulating pipework

- Reasonable operating costs

- Coils are made using aluminum or copper

- Externally it looks like a single plate construction, but internally metal tubes are present in multiple terms

- More rigid construction, hence more safety assurance

Enter Buying Requirement Details

Other Products in 'Evaporator Plants' category

"We are mainly dealing in India, Oman, Dubai, Saudi Arabia and U.A.E."

|

KETAV CONSULTANT

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese